Proweld Steel Fabrication

3D Shop Drawings in Wollongong

- Experts In Structural Steel Fabrication

- Experts In Structural Steel On-Site Installation

- Building Australia One Beam at a Time

What We Do

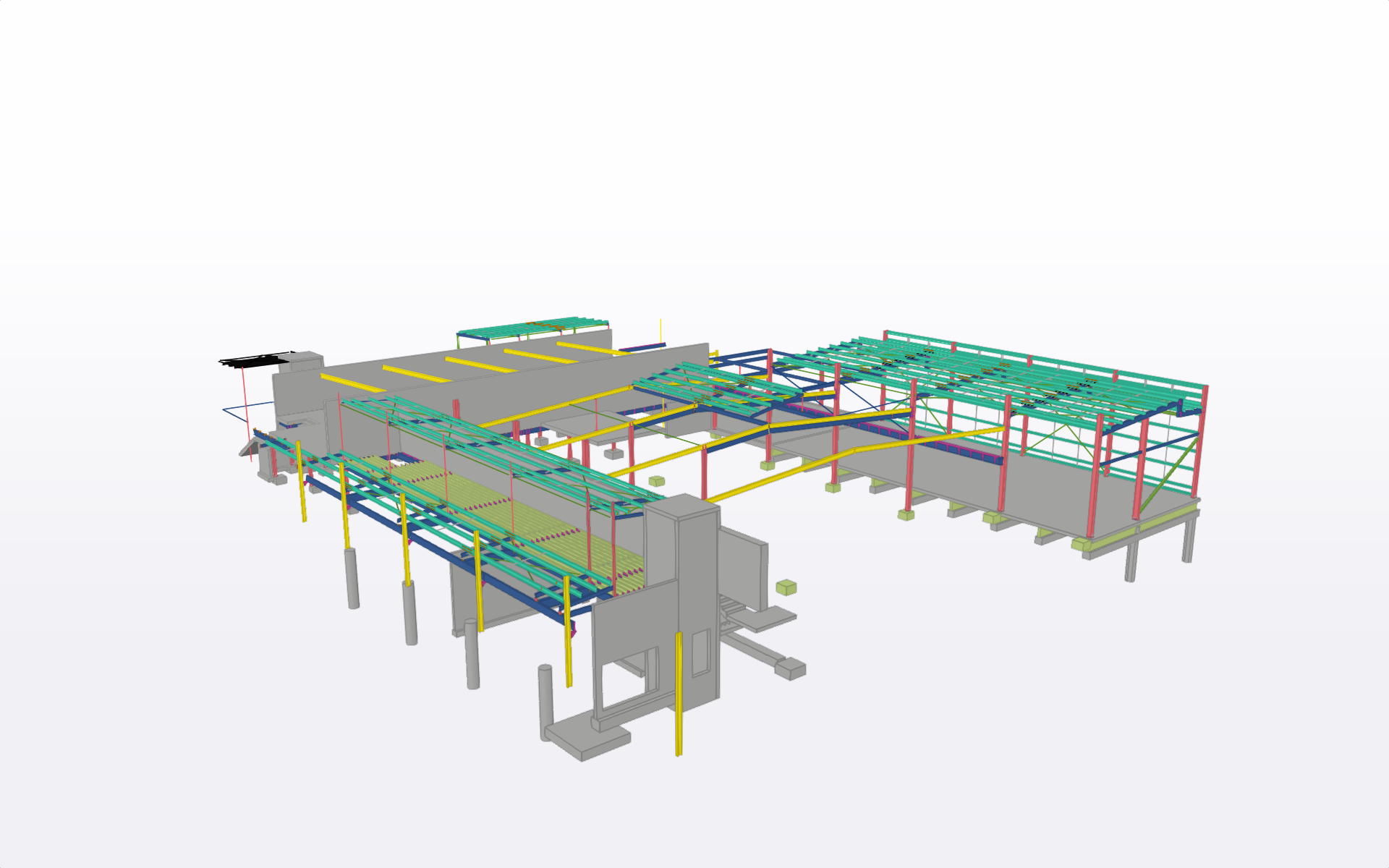

Detailed 3D Shop Drawings

Behind every strong build is a flawless plan. With Proweld Steel Fabrication in Wollongong, our 3D shop drawings turn complex steel fabrication concepts into clear, accurate models you can trust. By visualising every weld, joint and connection before fabrication begins, we help you avoid costly delays and reworks onsite.

These drawings aren’t just technical sketches — they’re fully coordinated plans designed to align seamlessly with architects, engineers and builders. This means fewer clashes during construction and smoother handovers from design to delivery.

3D drawings create a common language between teams. Builders see exactly how a staircase will connect. Owners get peace of mind seeing the final product before a single cut of steel is made.

Call

0428 413 254 today to discuss your project and see how our 3D shop drawings can bring clarity to your build. We service the

South Coast, Southern Highlands and Sydney areas.

Get a Free Quote

Contact Us

Thank you for contacting Proweld Steel Fabrication.

We will get back to you as soon as possible.

Oops, there was an error sending your message.

Please try again later.

DESIGNED FOR PRECISION

Built for Confidence & Accuracy

Visual certainty

With 3D shop drawings, you’re not left guessing. These models show every component in detail, giving you a clear view of the finished structure. You’ll know how each part fits together before fabrication even starts.

Reduced risk

Unexpected issues on site can derail timelines and budgets. By resolving conflicts digitally, our shop drawings catch problems early — saving you both money and stress down the track.

Faster approvals

Because drawings are detailed and highly accurate, they make it easier to gain fast approval from certifiers, clients and project managers. Everyone can see what’s planned and sign off with confidence.

Future-proofing

Our 3D drawings don’t just help you build today — they create a reliable record for future modifications, maintenance or extensions. That’s long-term value built into your project.

STREAMLINED SOLUTIONS

Why Choose Proweld Steel Fabrication

We don’t get caught up producing generic sketches or one-off markups. Our drafting process is purpose-built for project-based fabrication, delivering Wollongong’s builders and contractors detailed 3D shop drawings that bring precision to residential and commercial builds. We understand construction schedules, coordination between trades, and the importance of clear documentation on a fast-moving site.

From digital detailing to fully coordinated shop drawings and optional integration with fabrication, we provide reliability at every stage—ensuring your team has accurate plans, approvals, and visuals exactly when they’re needed, without compromise.

Need Help?

Frequently Asked Questions

What is residential steel fabrication used for?

The timeframe depends on the size and complexity of the project. A small residential feature may take only a few days, while a large structural project could take several weeks. The investment of time up front pays off, as it speeds up approvals, reduces site delays and ensures fabrication is done right the first time. The result is a smoother build and faster overall completion.

How do 3D shop drawings help prevent errors on site?

Construction sites are fast-paced, and mistakes can be expensive. 3D shop drawings act like a dry run for the project, highlighting issues before they ever reach the ground. For example, if two steel members clash or don’t align correctly, the problem is caught digitally and fixed before fabrication. This saves wasted materials, prevents delays and keeps the project running smoothly.

Are 3D shop drawings only used on large projects?

No. While they are critical for complex commercial and industrial builds, 3D shop drawings are just as valuable for residential and smaller projects. Even something like a custom staircase or balustrade benefits from having a detailed digital model. It ensures the finished piece fits perfectly, aligns with design expectations and avoids costly rework.